XXVI International Conference on Material Handling, Constructions and Logistics

2019

Functional Analysis and Multilevel DEM Simulation of the Innovative Tubular Push Conveying Principle

- Details Category:

- Activites /

- 2019

The tubular push conveyor, which is developed and marketed by the Bühler AG under the brand name TUBO, is an innovative conveying system for the transport of non-mineral bulk materials. It sets new standards, especially in agricultural and food technology, in terms of flexible conveying routes and simple design. Unlike today's systems, the bulk material is transported in a closed tube without a tension device (rope or chain) but by the help of push elements [1].

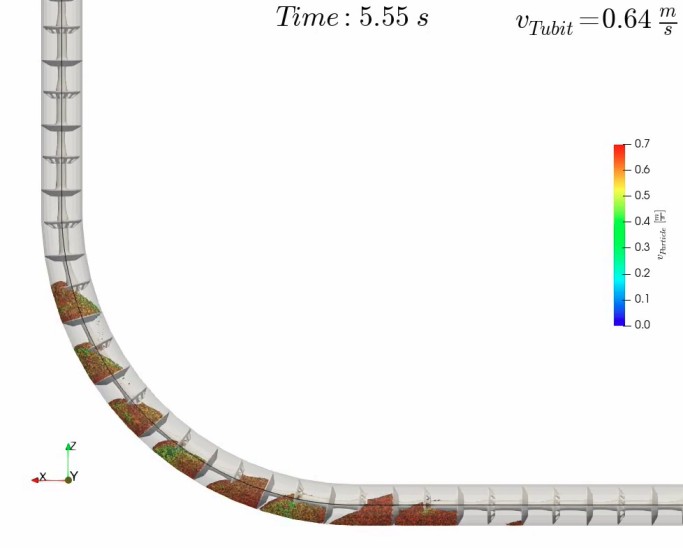

The paper will present the general layout of such conveyors as well as the basic calculation approaches for the motion resistances. The calculations will be compared with experimental measurements on an industrial sized test rig. For the further understanding DEM simulations are used to study the detailed motion behaviour of the push elements interacting with the bulk material. To consider the load dependent movement of the push elements, the so-called Multilevel DEM approach was developed. In particular, the motion resistances in vertical tube bends will be analysed with the DEM as shown in Fig. 1.

Fig. 1: Multilevel DEM simulation of the vertical bend of a tubular push conveyor

[1] Kamps, R.: Konzept und Realisierung eines Rohrfördersystems mit Schubelementen. PhD thesis. Bergische Universität Wuppertal. 2016

André Katterfeld

Professor

Otto-von-Guericke-Universitat

Magdeburg, Germany

- Details Category:

- Activites /

- 2019

Chemnitz, GermanySince the early 2000s efforts have been made to introduce a new way to calculate the lifetime for a rope in rope drives, nowadays implemented in EN 13001-3-2. This elaborated standard uses a cycle-based approach instead of a time-based approach, previously well-established for many years in DIN 15020-1 for example. Since its introduction, many discussions arose towards the cycle-based approach, especially regarding safety and multi-layer spooling. In 2015, a working group in TC96/SC3 has been established to revise ISO 16625 to adopt the cycle-based approach of EN 13001-3-2 and beyond that to enhance it. The enhancement addresses the special requirements of multi-layer spooling and provides a new foundation for the proof of fatigue strength. This “New Method” for the proof of fatigue strength is based on the Feyrer formula. The “New Method” was developed and verified in a collaboration between the Universities of Karlsruhe, Dresden, and Stuttgart. Combining the “New Method” with the cycle-based approach implemented in EN 13001-3-2 leads to the new approach for ISO 16625. The paper will report the initial situation, the developments of the “New Method” and describes the new approach for ISO 16625 subsequently.

Markus Golder

Professor

Technischen Universität Chemnitz

Chemnitz, Germany

- Details Category:

- Activites /

- 2019

Logistics can be defined as a science managing the flow of resources through supply chains in terms of distribution logistics (moving goods from the manufacturer through any intermediaries, to the final customer) and intralogistics (moving goods within the walls of a production facility or distribution center) associated with the informational flow. Industry 4.0, internet of Things, Digital Transformation and Digitization, Smart Intralogistics, Intralogistics 4.0 are just some of the phrases, which are used to describe the (near) future of the logistics. In the framework of the invited paper, trends, technologies and application of the next generation intralogistics will be presented and discussed. Along with presentation, some prototypes developed by the Laboratory of logistics systems at Faculty of Logistics University of Maribor will be shown.

Tone Lerher

Professor

University of Maribor

Faculty of Mechanical Engineering

Maribor, Slovenia

- Details Category:

- Activites /

- 2019

Dr. Johannes Hinckeldeyn and Prof. Jochen Kreutzfeldt

Institute of Technical Logistics

Hamburg University of Technology, Germany

- Details Category:

- Activites /

- 2019

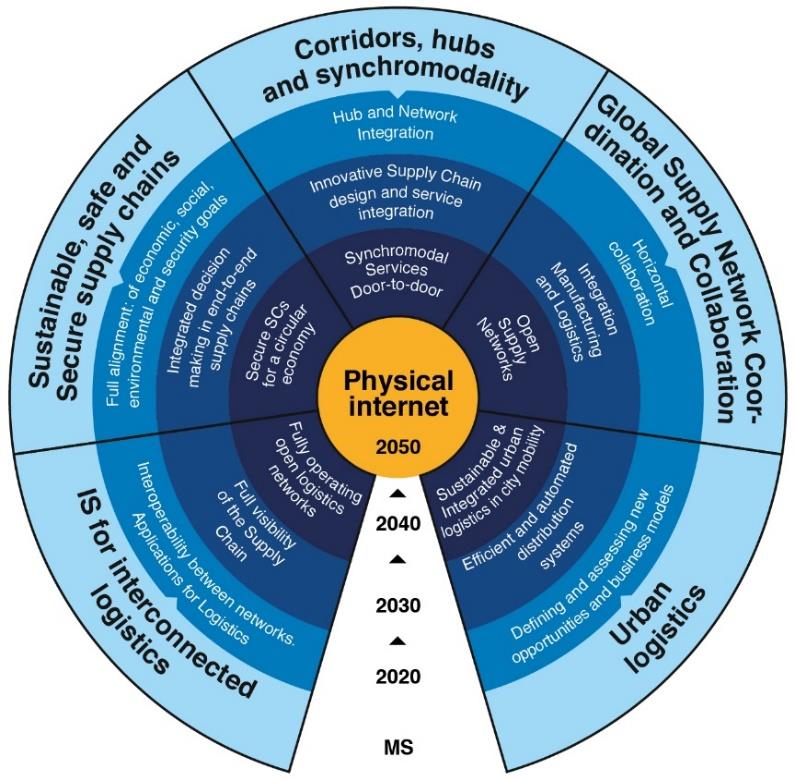

“In logistics, the Physical Internet (PI) is an open global logistics system founded on physical, digital, and operational interconnectivity, through encapsulation, interfaces and protocols.1 The Physical Internet is intended to replace current logistical models.”2 3 As there are different layers of functionality and a wide-range perspective for 2050 in the PI, this contribution tries to focus on the technical achievements and first successful implementations of the PI in Austria and Europe.

Modular boxes, PI hubs and their technology accordingly play a major role within effective logistic systems, following the PI fundamentals and forming the PI components and logistic installations. When goods are encapsulated in boxes, and boxes united to unit loads this unit loads can be composed to logistic needs individually by saving space and increasing volume usage in conventional truck transport. As a PI box never runs empty, the PI cares for optimized routing through the network. By avoiding empty miles and wasting packaging of different layers of cartons, cases and plastic sheets, the PI box logistic is also more sustainable and environmental friendly than conventional handling with pallets and skids.

Implementing the main ideas and their benefits of the PI to actual logistics is not a single step but means a change in thinking and collaborating. The presentation will introduce the idea of the PI briefly, outline concrete scenarios and show successful first installations, that follow the PI Manifesto1 (see above). Therefore global players from research and industry within the largely growing worldwide community of the PI try to convince, influence, prototype and perform a change in thinking about logistics.

Austria especially is very happy, to be a pioneer within this logistics research. Many funded projects, as described in the presentation, have been elaborated together with national and international research community and global industrial players. The PI idea is powered by technology platforms like ALICE4, who’s members developed a roadmap towards a working Physical Internet by 2050 and major steps on its way.

PI receives dedicated funding from the European Commission and many national funding programs. With its internationality it is the one and only global logistics research approach and is therefore very attractive to young researchers. The largely growing output of the annual International Physical Internet Conference proves the success of the approach.

Roadmap to the Physical Internet by ALICE4

1 Montreuil, Benoit. "Physical Internet Manifesto, version 1.11.1", CIRRELT Interuniversity Research Center on Enterprise Networks, Logistics and Transportation, Quebec, 28 November 2012. Retrieved on 6 February 2013.

2 Montreuil, Benoit. http://tedxtalks.ted.com/video/Benoit-Montreuil-at-TEDxBuchare

3 Trebilcock, Bob. "Physical Internet Initiative: Pipedream or possibility?", Logistics Management magazine, 1 March 2012. Retrieved on 12 February 2013.

4 http://www.etp-logistics.eu/, a short introduction video to the PI by ALICE: https://www.youtube.com/embed/PJyzFaKOXnY

Christian Landschützer

Assoc. Professor

Institut für Technische Logistik

Graz, Austria

Host city and venue - Belgrade

As a regional hub for business, engineering, and innovation, Belgrade provides an excellent setting for an international conference. The city is well connected by air, road, and rail, making it easily accessible for participants from across Europe and beyond.

The conference venue is situated in a modern, fully equipped facility, offering high-quality technical infrastructure and comfortable spaces for lectures, workshops, and networking. Together, the city and venue create an inspiring environment for professional exchange, collaboration, and knowledge sharing. Read more...

Latest news

-

MHCL 2026: Celebrating 50 Years of Excellence

25 January 2026

We are excited to announce the XXVI International Conference MHCL 2026, taking place at Faculty of Mechanical Engineering, University of Belgrade, Serbia from September 23–25, 2026.This year’s... -

10 September 2024

MHCL 2024 - Conference agenda -

28 August 2024

New information about the conference MHCL 2024 -

16 July 2024

Updated information about MHCL Conference 2024 -

17 January 2024

Welcome to MHCL 2024